OEM manufacturer Machine Toe Jack - Machinery Jack TB100 – Hardlift

OEM manufacturer Machine Toe Jack - Machinery Jack TB100 – Hardlift Detail:

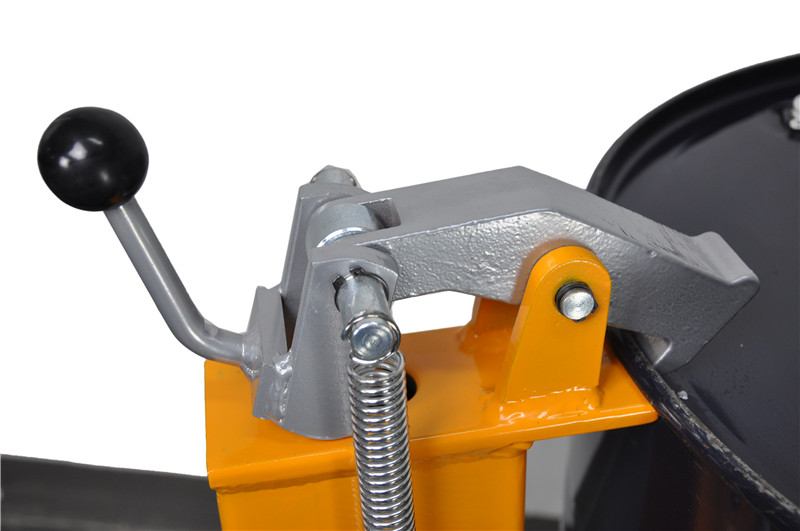

▲ Easily glides over pallet to quickly load or unload 55-gallon drums,Grabs drums from the middle of a standard pallet with a drum claw grab,raises the drum up, and redistributes them throughout the facility.

▲ Also removes drums from the corner of containment skids.

Feature

Matured quality;

Most popular model in EU and US market;

Price advantage than other items with same function.

| Model | DT250 | DT300A |

| Lifting Capacity | 250kg / 550lbs | 300KG |

| Lifting Height | 245mm / 13.58” | 290MM |

| Drum Size | 572mm (22.5” Diameter), 210 Lifters (55 gallon) | 572mm (22.5” Diameter), 210 Lifters (55 gallon) |

| Net Weight | 42kg / 93lbs | 43KG |

Floor jack

In a floor jack (aka ‘trolley jack’) a horizontal piston pushes on the short end of a bellcrank, with the long arm providing the vertical motion to a lifting pad, kept horizontal with a horizontal linkage. Floor jacks usually include castors and wheels, allowing compensation for the arc taken by the lifting pad. This mechanism provides a low profile when collapsed, for easy maneuvering underneath the vehicle, while allowing considerable extension.

Bottle jack

“Bottle jack” redirects here. For the meat-roasting device, see Roasting jack.

A bottle jack or whiskey jack is a jack which resembles a bottle in shape, having a cylindrical body and a neck. Within is a vertical lifting ram with a support pad of some kind fixed to the top. The jack may be hydraulic or work by screw action. In the hydraulic version, the hydraulic ram emerges from the body vertically by hydraulic pressure provided by a pump either on the baseplate or at a remote location via a pressure hose. With a single action piston the lift range is somewhat limited, so its use for lifting vehicles is limited to those with a relatively high clearance. For lifting structures such as houses the hydraulic interconnection of multiple vertical jacks through valves enables the even distribution of forces while enabling close control of the lift.

The screw version of the bottle jack works by turning a large nut running on the threaded vertical ram at the neck of the body. The nut has gear teeth, and is generally turned by a bevel gear spigotted to the body, the bevel gear being turned manually by a jack handle fitting into a square socket. The ram may have a second screwed ram within it, which doubles the lifting range telescopically.

Bottle jacks have a capacity of up to 50 tons and may be used to lift a variety of objects. Typical uses include the repair of automobiles and house foundations. Larger, heavy-duty models may be known as a barrel jack.

This type of jack is best used for short vertical lifts. Blocks may be used to repeat the operation when a greater amount of elevation is required.

Product detail pictures:

Related Product Guide:

"Control the quality by the details, show the power by quality". Our enterprise has strived to establish a remarkably efficient and stable team team and explored an effective excellent control system for OEM manufacturer Machine Toe Jack - Machinery Jack TB100 – Hardlift , The product will supply to all over the world, such as: Barbados, Pakistan, Guyana, Furthermore, all of our products are manufactured with advanced equipment and strict QC procedures in order to ensure high quality. If you are interested in any of our products, please don't hesitate to contact us. We will do our best to meet your needs.

We have worked with many companies, but this time is the best,detailed explanation, timely delivery and quality qualified, nice!