OEM Customized Hydraulic Toe Lift Jack – Forklift Jack – Hardlift

OEM Customized Hydraulic Toe Lift Jack – Forklift Jack – Hardlift Detail:

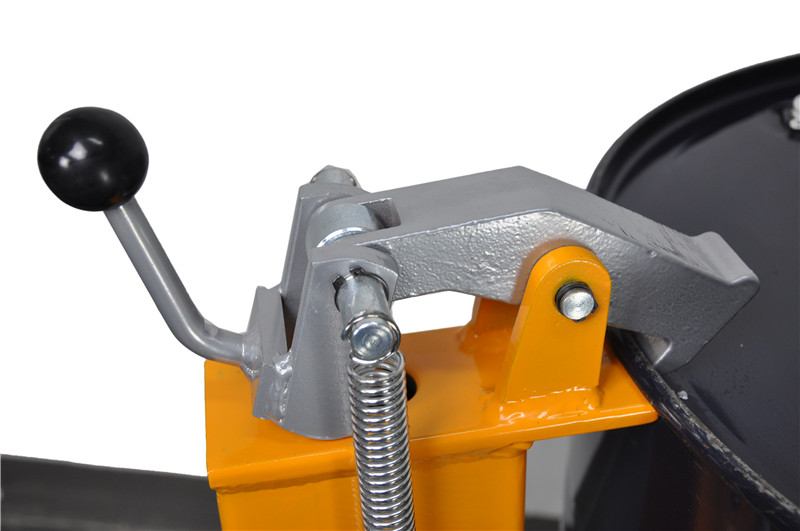

▲ Easily glides over pallet to quickly load or unload 55-gallon drums,Grabs drums from the middle of a standard pallet with a drum claw grab,raises the drum up, and redistributes them throughout the facility.

▲ Also removes drums from the corner of containment skids.

Feature

Matured quality;

Most popular model in EU and US market;

Price advantage than other items with same function.

| Model | DT250 | DT300A |

| Lifting Capacity | 250kg / 550lbs | 300KG |

| Lifting Height | 245mm / 13.58” | 290MM |

| Drum Size | 572mm (22.5” Diameter), 210 Lifters (55 gallon) | 572mm (22.5” Diameter), 210 Lifters (55 gallon) |

| Net Weight | 42kg / 93lbs | 43KG |

Hydraulic jack

The working principle of a hydraulic jack

In 1838 William Joseph Curtis filed a British patent for a hydraulic jack.

In 1851, inventor Richard Dudgeon was granted a patent for a “portable hydraulic press” – the hydraulic jack, a jack which proved to be vastly superior to the screw jacks in use at the time.

Hydraulic jacks are typically used for shop work, rather than as an emergency jack to be carried with the vehicle. Use of jacks not designed for a specific vehicle requires more than the usual care in selecting ground conditions, the jacking point on a vehicle, and to ensure stability when the jack is extended. Hydraulic jacks are often used to lift elevators in low and medium rise buildings.

A hydraulic jack uses a liquid, which is incompressible, that is forced into a cylinder by a pump plunger. Oil is used since it is self lubricating and stable. When the plunger pulls back, it draws oil out of the reservoir through a suction check valve into the pump chamber. When the plunger moves forward, it pushes the oil through a discharge check valve into the cylinder. The suction valve ball is within the chamber and opens with each draw of the plunger. The discharge valve ball is outside the chamber and opens when the oil is pushed into the cylinder. At this point the suction ball within the chamber is forced shut and oil pressure builds in the cylinder.

Product detail pictures:

Related Product Guide:

The organization upholds the philosophy of "Be No.1 in good quality, be rooted on credit history and trustworthiness for growth", will keep on to provide previous and new customers from home and overseas whole-heatedly for OEM Customized Hydraulic Toe Lift Jack – Forklift Jack – Hardlift , The product will supply to all over the world, such as: Croatia, Malta, Peru, Based on our automatic production line, steady material purchase channel and quick subcontract systems have been built in mainland China to meet customer's wider and higher requirement in recent years. We have been looking forward to cooperating with more clients worldwide for common development and mutual benefit!Your trust and approval are the best reward for our efforts. Keeping honest, innovative and efficient, we sincerely expect that we can be business partners to create our brilliant future!

On this website, product categories is clear and rich, I can find the product I want very quickly and easily, this is really very good!